30-40t/H Mobile and Continuous Asphalt Mixer (GLB30)

- Price can be negotiated

- 1 Unit

- 46 Unit

- 30 days

Product Description

30-40T/H Mobile And Continuous Asphalt Mixer(GLB30)

1.Major Parameter

A.Type: GLB30/40

B.Model: modular, easy to assemble and disassemble, movable and continuous.

C.Outputting: 30-40T/H

D.Power: 32KW

2. 2.1Cold aggregate hopper, with separate net set at the storage's door

A If set as flat: 4m3

B 5.5 m3,If set as pile: 32KW

C Quantity: 3

2.2 Aggregate Conveyer Belt

A Type: channel frame support with three points

B Outputting: 60t/h

C Belt width: 500

D Geared motor: BWD13-17-1.5kw

2.3 feeding belt

A Type: channel frame support with three points

B Outputting: 60t/h

C Belt width: 500

3. Drying roller

3.1 A. Type: tilt roller which has rotary and counter-current fluent

B Productivity: 40t/h in the station of moisture content is 3% and outputting material temperature is 150ºC

C Roller specification: φ1200×4800

D Geared Motor: BWY27-29-7.5kw

E Drive by gear

3.2 Coal mill used on the coal burning plant

A Type: FD-65

B Power: 11kw

3.3 Blower

A Type: Y4-72-5A

B Power: 2.2kw-2P

3.4 oil burner

A Oil pump: 1.1KW

B Blower: 15KW

4. Asphalt Supplying System

It has 50 Asphalt pumps with 4kw.

5. Dust Reducing Device

A. Clean the dust by wind which induced at the end

B . Draft fan: 15KW

6. Finished material storage: 1 M3

7. Control Cabinet

1.Major Parameter

A.Type: GLB30/40

B.Model: modular, easy to assemble and disassemble, movable and continuous.

C.Outputting: 30-40T/H

D.Power: 32KW

2. 2.1Cold aggregate hopper, with separate net set at the storage's door

A If set as flat: 4m3

B 5.5 m3,If set as pile: 32KW

C Quantity: 3

2.2 Aggregate Conveyer Belt

A Type: channel frame support with three points

B Outputting: 60t/h

C Belt width: 500

D Geared motor: BWD13-17-1.5kw

2.3 feeding belt

A Type: channel frame support with three points

B Outputting: 60t/h

C Belt width: 500

3. Drying roller

3.1 A. Type: tilt roller which has rotary and counter-current fluent

B Productivity: 40t/h in the station of moisture content is 3% and outputting material temperature is 150ºC

C Roller specification: φ1200×4800

D Geared Motor: BWY27-29-7.5kw

E Drive by gear

3.2 Coal mill used on the coal burning plant

A Type: FD-65

B Power: 11kw

3.3 Blower

A Type: Y4-72-5A

B Power: 2.2kw-2P

3.4 oil burner

A Oil pump: 1.1KW

B Blower: 15KW

4. Asphalt Supplying System

It has 50 Asphalt pumps with 4kw.

5. Dust Reducing Device

A. Clean the dust by wind which induced at the end

B . Draft fan: 15KW

6. Finished material storage: 1 M3

7. Control Cabinet

| 1.Major Parameter |

| A.Type: GLB30/40 |

| B.Model: modular, easy to assemble and disassemble, movable and continuous. |

| C.Outputting: 30-40T/H |

| D.Power: 32KW |

| 2. 2.1Cold aggregate hopper, with separate net set at the storage's door |

| A If set as flat: 4m3 |

| B 5.5 m3,If set as pile: 32KW |

| C Quantity: 3 |

| 2.2 Aggregate Conveyer Belt |

| A Type: channel frame support with three points |

| B Outputting: 60t/h |

| C Belt width: 500 |

| D Geared motor: BWD13-17-1.5kw |

| 2.3 feeding belt |

| A Type: channel frame support with three points |

| B Outputting: 60t/h |

| C Belt width: 500 |

| 3. Drying roller |

| 3.1 A. Type: tilt roller which has rotary and counter-current fluent |

| B Productivity: 40t/h in the station of moisture content is 3% and outputting material temperature is 150ºC |

| C Roller specification: φ1200×4800 |

| D Geared Motor: BWY27-29-7.5kw |

| E Drive by gear |

| 3.2 Coal mill used on the coal burning plant |

| A Type: FD-65 |

| B Power: 11kw |

| 3.3 Blower |

| A Type: Y4-72-5A |

| B Power: 2.2kw-2P |

| 3.4 oil burner |

| A Oil pump: 1.1KW |

| B Blower: 15KW |

| 4. Asphalt Supplying System |

| It has 50 Asphalt pumps with 4kw. |

| 5. Dust Reducing Device |

| A. Clean the dust by wind which induced at the end |

| B . Draft fan: 15KW |

| 6. Finished material storage: 1 M3 |

| 7. Control Cabinet |

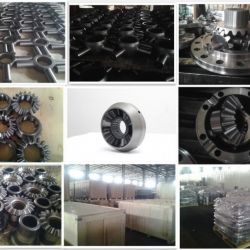

Product Images

/

/